MARITIME INDUSTRY

INTEGRATED NAVIGATION SYSTEMS

MARINE AUTOMATION

AUTOMOTIVE INDUSTRY

PLC PROGRAMMING

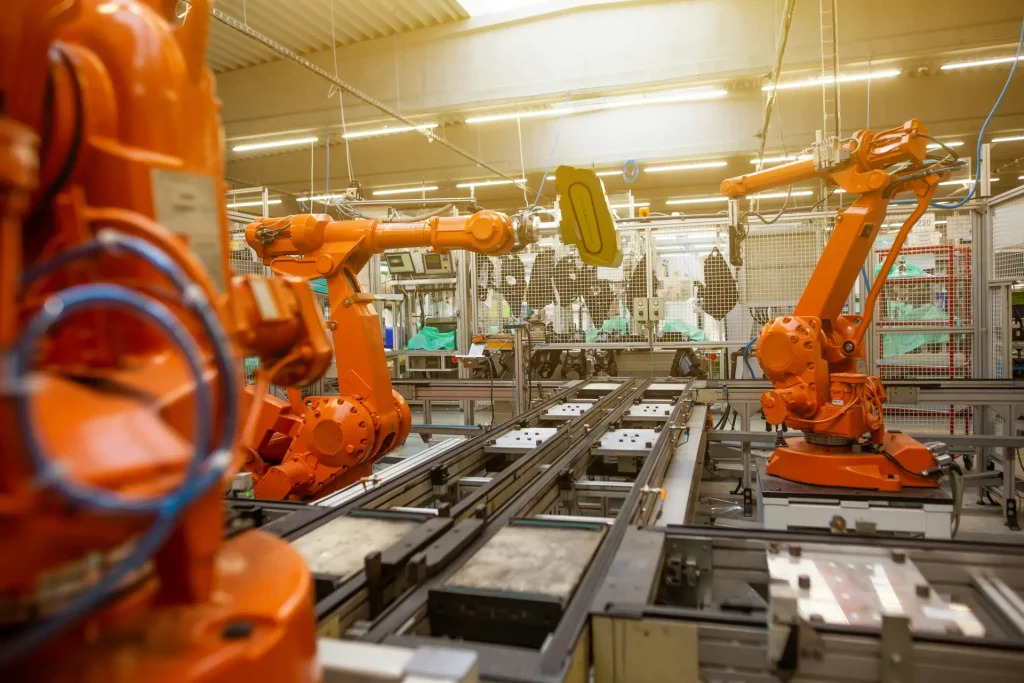

ROBOT PROGRAMMING

About.

DOMAT is a company whose experience has been built over years of work in industrial and maritime sectors. The core area of activity is programming PLC controllers forming part of production lines in the automotive industry. The company also undertakes smaller projects, offering flexible solutions tailored to client needs. Experience includes Siemens and Mitsubishi PLCs as well as Siemens HMI operator panels. These skills are also applied in maritime projects.

Our competencies also cover commissioning and calibration of NACOS Platinum Integrated Navigation Systems by Wärtsilä Sam Electronics along with peripheral devices, as well as Marine Automation Systems by Wärtsilä Lyngsø Marine. We also carry out electrical works related to installation and assembly. More details are available on LinkedIn (link in the navigation panel).

Offer.

Immediate Service Availability

Thanks to an efficient decision-making process, our services can be available locally within a few hours of receiving an inquiry, and worldwide even within 48 hours, depending on travel time to the site.

Siemens PLC Programming

Extensive experience in programming Siemens PLCs includes a wide range of automation solutions using Step7 and TIA Portal. Expertise covers HMI panels and various industrial peripherals, as well as programming Siemens and Bosch Rexroth servo drives for optimized integration and performance.

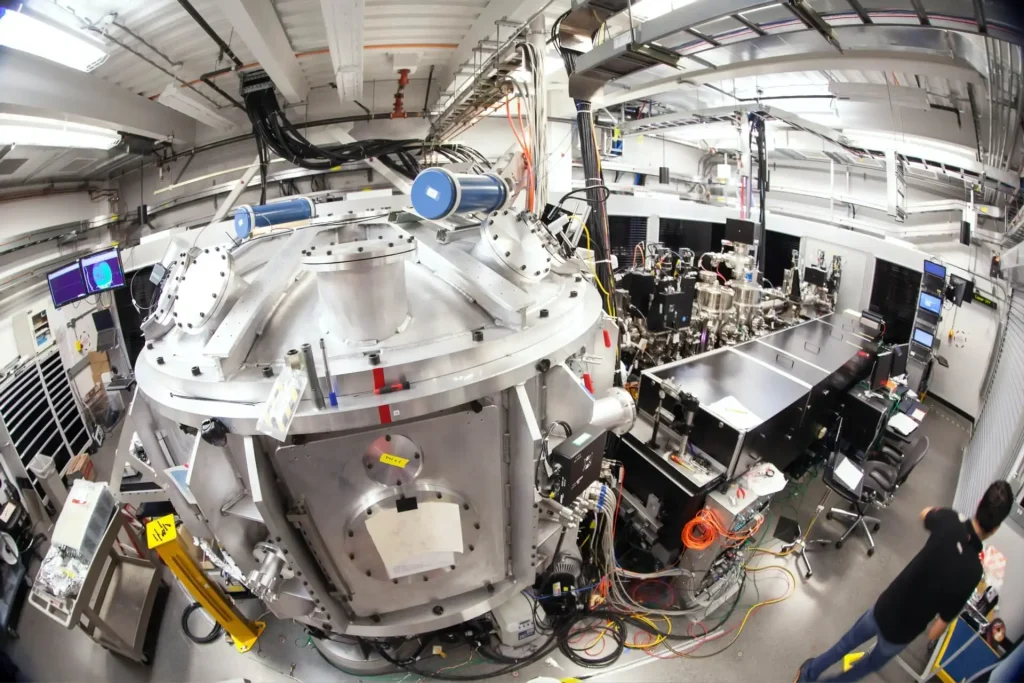

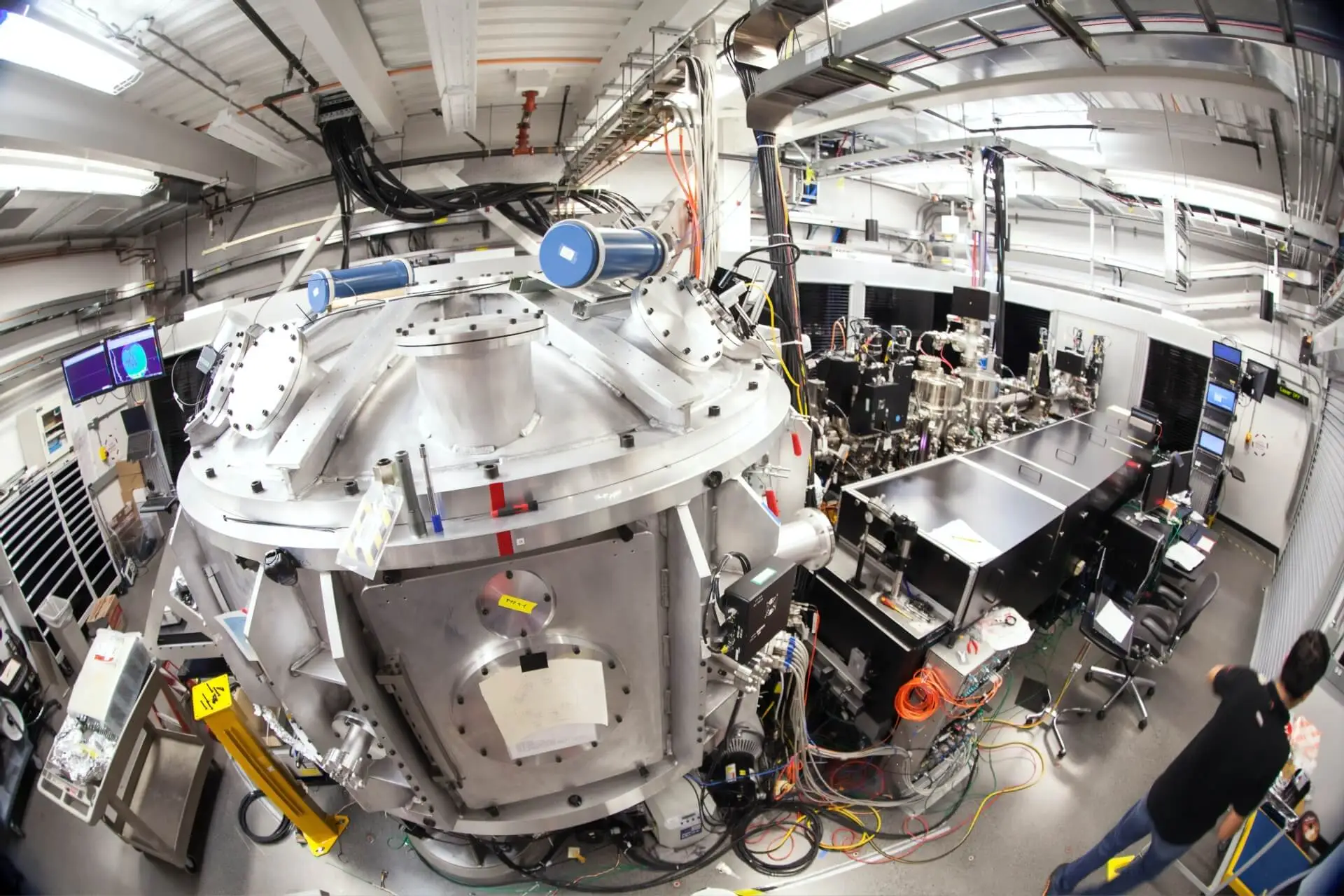

Integrated Navigation Systems

In-depth experience with NACOS Platinum systems by Wärtsilä Sam Electronics and peripheral devices provides a solid foundation. Skills include working with navigation aids such as DGPS for accurate positioning, AIS for vessel monitoring, and weather stations for meteorological data, ensuring effective and safe maritime operations.

Robot Programming

Expertise in programming Mitsubishi industrial robots allows implementation of advanced automation solutions tailored to production requirements. Precise position programming ensures accurate movements, while optimization of pick & place processes improves efficiency and production output.

Marine Automation

Significant experience in commissioning NACOS Platinum Marine Automation Systems by Wärtsilä Lyngsø Marine ensures effective system integration, enhancing vessel management and operational safety. Technical knowledge allows solutions tailored to the maritime industry’s needs.

Electrical Works in the Maritime Sector

Proficiency in shipboard installation and connection works ensures compliance with marine standards. Experience includes modernization of navigation and automation systems, component upgrades, efficiency improvement, and enhanced operational safety.

Projects.

We have completed a wide range of projects in industrial and maritime sectors. In the industrial field, tasks primarily involved programming PLCs and commissioning peripheral devices for the automotive industry. Work included developing new programs, modifying existing ones, and testing complete machines.

At the same time, maritime projects included modernization of integrated navigation systems on seagoing vessels. The scope involved replacing outdated systems with new ones, installation, commissioning, and handover to the shipowner. More information is available on LinkedIn (link in the navigation panel).

COMPLETED PROJECTS

EATON

ITALY

Design, software preparation, and commissioning of an automated inverter assembly line using Siemens S7 PLC (TIA18) and Siemens HMI (WinCC), ensuring high functionality and reliability.

DAIMLER

GERMANY

Commissioning of an automated electric motor assembly line built for Daimler in Bremen using Siemens S7 PLC (TIA15.1) and Siemens HMI (HMI Pro), enabling production on a larger scale.

FORD

UNITED KINGDOM

Commissioning of the electric motor production line at Ford in Liverpool, ensuring operational readiness for new production demands.

CONTINENTAL TEVES

PRODUCTION SUPPORT

MEXICO

Support of production through programming and reprogramming of brake caliper lines, maximizing efficiency and minimizing downtime.

VW

GERMANY

Programming of electric motor assembly lines for VW in Kassel, ensuring stable processes and high-quality output.

VW ID BUZZ

GERMANY

Commissioning of the body transport line for VW ID Buzz in Hanover, enabling production of the new vehicle model.

UAB HELLA

LITHUANIA

Programming of Mitsubishi robots at UAB Hella Lithuania, including defining new pick & place positions to streamline operations and increase precision.

CONTINENTAL

TEVES

MEXICO

Relocation and recommissioning of a brake caliper assembly line from the USA to Mexico, including modification of Siemens PLC software and Mitsubishi robot programming, ensuring seamless production continuity.

EBERSPÄCHER

POLAND

Final commissioning of the production line for heating modules for electric cars at Eberspächer, optimizing production processes and meeting rising market needs.

HOFER POWERTRAIN

PRODUCTS

UNITED KINGDOM

Commissioning of an advanced automatic test line for gearbox assemblies at Hofer Powertrain Products using Siemens S7 PLCs, ensuring reliability and consistent production quality.

ACCUMOTIVE

GERMANY

Commissioning of an automated production line for electric vehicle batteries in Kamenz using Siemens S7 PLCs. The project enabled the start of production to meet market demand.

RO-RO VESSEL

BEGONIA SEAWAYS

Upgraded Wärtsilä Sam Electronics navigation system on Begonia Seaways, significantly increasing navigational accuracy and aligning the vessel with modern operational standards.

RO-RO VESSEL

PRIMULA SEAWAYS

Retrofit of the navigation system on Primula Seaways using Wärtsilä Sam Electronics technology, enhancing navigational precision and compliance with maritime regulations.

FERRY

MS VICTORIA 1

Modernization of Wärtsilä Sam Electronics navigation system on MS Victoria 1, improving vessel navigation capabilities and ensuring compliance with current safety standards.